In addition, logistics and transportation is one of the key factors when making cars. For this reason, the plastic pallet plays a transcendental role in the automotive sector, not only for facilitating reverse logistics solutions but also for being the perfect element to safely transport, from the supplier to the main automobile manufacturers, the largest part of the pieces.

However, this is not the only reason why the plastic pallet is considered, by the Naeco, (previously Nortpalet) team of professionals, the necessary and essential complement to improve the efficiency of the logistics supply chain in the automotive sector. Do not miss out on the other good reasons why the plastic pallet is the perfect solution!

Why is the plastic pallet necessary in the automotive sector?

It is a reality that plastic pallets are occupying an increasingly solid and protagonist gap in the transport and logistics storage of the automobile industry, especially when distributing products around the world, but why?

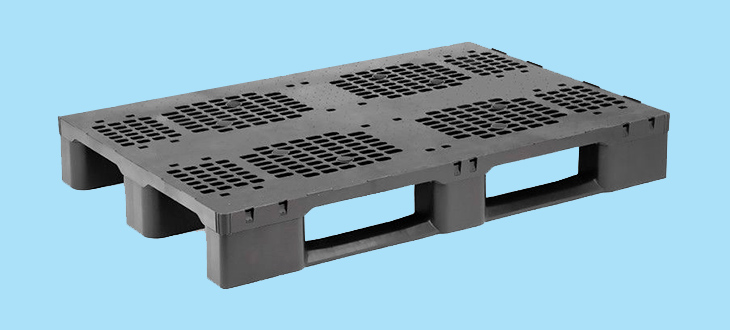

• They offer greater product protection: As they are pallets made of plastic, they remain unchanged in weight and shape throughout their entire useful life, which guarantees their stability and the loads they support.

• Protect the product against electrostatic charges: when it comes to electrical components, the plastic pallet can be added with an antistatic component protecting the electronic components.

• They ensure absolute cleanliness. They can be easily cleaned and disinfected. In addition, it does not detach nails or splinters so they can enter the production lines, without damaging or dirtying them. This represents a significant saving in maintenance costs of the facilities.

• They are extremely durable and resistant. Plastic pallets have a longer useful life when compared to their equivalent in other materials, a low rate of fractures. Therefore, they are ideal elements to support logistics circuits, the great weight of some parts and products, resist extreme weather conditions, chemical spills and even corrosion. For that reason, one of the options chosen by most of the companies in the industry is the EXPERT range.

• They allow the traceability of products through RFID or with barcode or QR labels.

• Facilitate automated transport through roller paths.

• They also guarantee automated storage on shelves.

• Its high stacking capacity.

• They are lightweight.

• They are Reusable Transport Elements (ERT). Taking into account that the automotive sector is a leader in so-called reverse logistics solutions, most of the parts that are transported from suppliers to the assembly factories of the main automobile manufacturers are contained in what is known as Reusable Elements of Transport (ERT), that is, plastic equipment, which returns to the production centers once emptied to be loaded again with new parts, restarting the cycle.

• Respectful with the environment, they favor sustainability and ZERO WASTE strategies: they are products made from recycled materials and once their useful life cycle ends, they are 100% recyclable and can be integrated into the Naeco, (previously Nortpalet) production system.

What advantages does its use offer to the automotive industry?

Plastic pallets have proven over the years that, thanks to their high durability, they are the most efficient and beneficial option for large supply chains in the automotive industry. However, these are not the only advantages, it also has many other important ones to highlight. These are some of the main ones:

• High load security.

• They are easy to handle. Especially vacuum equipment to be lighter.

• They require less maintenance of production positions.

• They improve the conservation of the facilities.

• They reduce the logistics cost per movement.

• They are impervious to oils, greases, and all kinds of solvents.

• They are light.

• Easy to clean and avoid the accumulation of pests and bacteria. Perfect for international shipments.

Conclusion

The internal flow of material in the production of components for the automotive industry requires specific logistics solutions, capable of protecting both the heavy and large parts of the sector as well as the most fragile and delicate electronic components.

That is one of the reasons why the Naeco, (previously Nortpalet) team considers that plastic pallets, due in part, to their robust, resistant character and high durability, are the safest option when it comes to guaranteeing the transfer and storage of parts successfully, largely ending untimely interruptions and downtime that result in high temporary economic costs for the company. And what logistics elements does your company use to improve the transport of products?